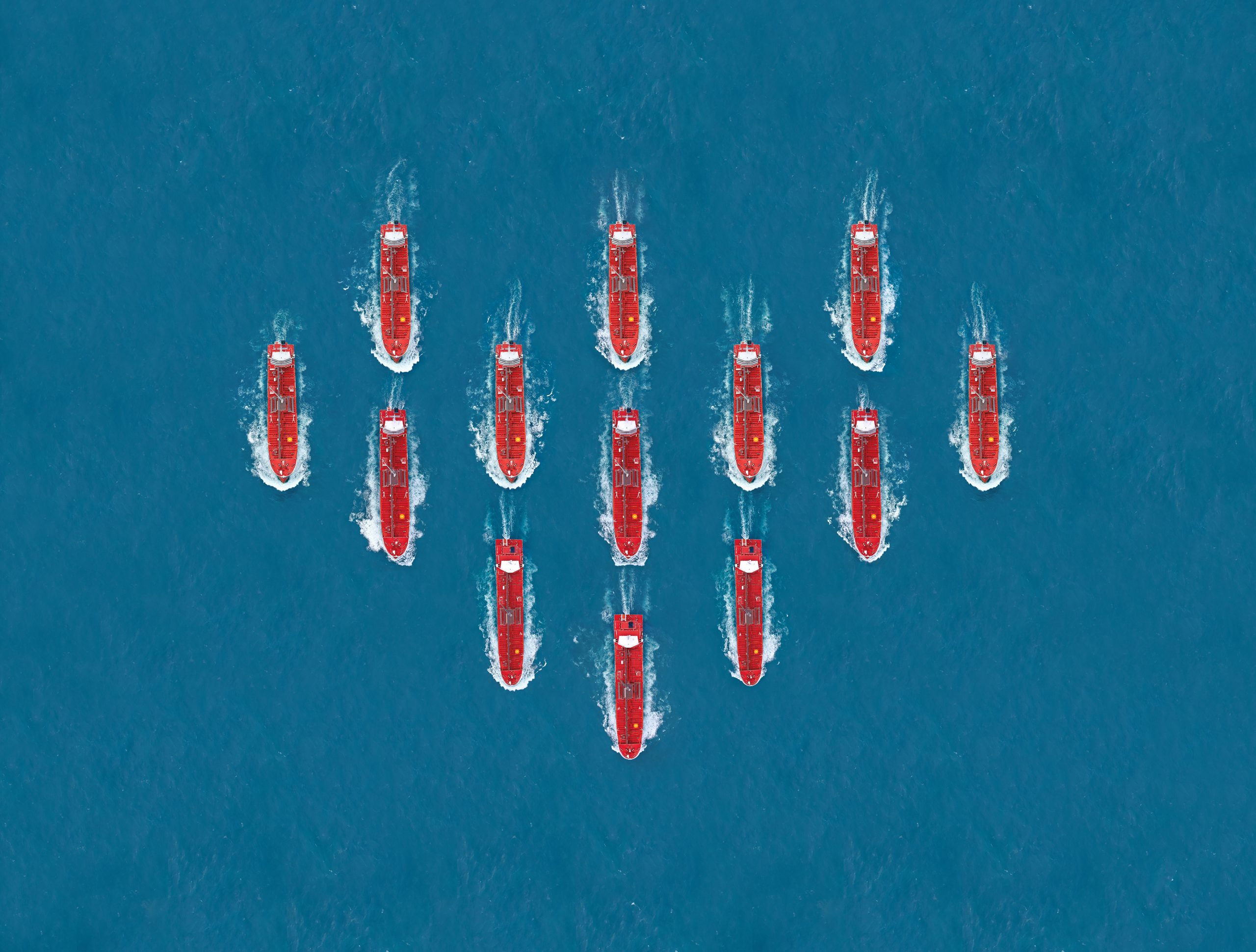

Stena Teknik supports joint venture Proman Stena Bulk in their newbuilding program of six methanol-powered vessels. Each vessel will use 12,500 tonnes per annum of methanol as a marine fuel, significantly reducing emissions in their normal commercial operations compared to conventional marine fuels. Stena Teknik has been involved in specification and contract development as well as project management from contract signing to delivery, including site supervision.

Energy Efficiency is crucial both in our existing fleet and newbuilds. Not only does it contribute to cutting costs in a context where fuels are constantly getting more expensive, but it also reduces our carbon dioxide emission with immediate effect. At Stena Teknik, we support the other Stena business units with investment studies to further cut down the fuel consumption and develop new concept designs to push the boundaries of efficient transportation by sea.

Stena Teknik is proactive in the marine life protection domain. Together with research institutes, NGOs and marine biologists, Stena Teknik is evaluating Stena’s impact on marine life and identifying measures to limit it. This includes finding synergies between underwater radiated noise reduction and energy efficiency improvements, and establishing strategies for whale protection to limit the vessels’ impact in areas occupied by vulnerable cetacean species.

Battery Electrification is part of both the short- and long-term pathway for the decarbonization of shipping, and already today most new RoPax vessels are equipped with an Energy Storage System (ESS). We support the business units with electrification and hybridization, and each day takes us closer to a fully Battery Electric Vessel.

Stena Teknik is providing intelligence on alternative (green) fuels with a data-driven and scientific approach. With regulatory, market, engineering and scientific expertise and data, Stena Teknik builds scenarios and advises Stena in the energy transition. This includes driving projects which enable uptake of green fuels.

Our focus on Smart Ships prioritizes safety and energy efficiency through collaboration with industry and organizations. Key objectives include enhanced reliability and safety, reducing maintenance, decreased energy consumption, and minimizing the environmental footprint.

Stena Teknik is a common resource for all maritime related business in the Stena Sphere and has the role of an expert function in primarily marine technology.

The Stena Teknik team has competence to handle all the stages of newbuilding and projects – from the concept to delivery.